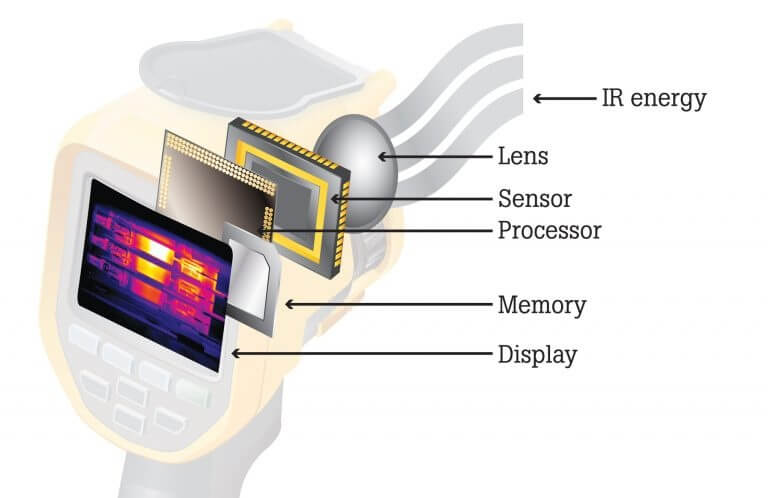

Infrared thermography is a high-tech tool that allows you to see inside of electrical systems without opening them up. It can identify hot spots in your system and predict failures before they happen, providing valuable information about your electrical system reliability. Infrared thermography uses infrared cameras to take images of components such as transformers, switchgear and panels through the use of lasers. These images provide real-time temperature information which helps determine where heat generation is occurring. This technology enables you to get an accurate picture of how much heat an item produces when it’s running at peak capacity or has been subjected to prolonged periods of stress like prolonged periods of operation on one particular circuit within an area (i.e., we have switched over some circuits).

Image credit: https://eng.unimelb.edu.au/study/professional-development/itc-infrared-thermography-category-1

Electrical systems present many opportunities for faults and failures.

Electrical systems present many opportunities for faults and failures. The complexity of these systems makes it difficult to locate faults, which can cause fires or damage to the electrical system. In addition, the failure of a component due to an intermittent fault may not be identified until it is too late for corrective action.

Failure of an electrical component may result in injury or death if not detected and corrected quickly. It could also result in loss of revenue if you do not detect and correct failures with your current equipment before they cause long-term damage or financial loss

Components such as electrical panels, transformers and switchgear are susceptible to overheating that may result in equipment failure, fire or structural damage.

Overheating is the buildup of heat inside a system, causing equipment failure, fire or structural damage. Infrared thermography can help identify overheating before it causes any damage by detecting the temperature of electrical panels, transformers and switchgear.

The key to identifying the source of an issue is knowing what temperatures are normal for each component in your electrical system. When you know what’s normal for these parts, you’ll be able to spot any anomalies quickly so you can take corrective action before anything goes wrong!

Most electrical faults produce heat before they produce catastrophic or visible signs of failure.

Infrared thermography is an effective method for detecting electrical faults in the distribution network. Most faults produce heat before they cause catastrophic or visible signs of failure, which means that an infrared thermographer can detect them early on and prevent damage to equipment.

Infrared thermography detects faults by taking measurements at multiple points throughout your system using specialized infrared cameras. The measurements are then analyzed by computer software to determine if there are any problems with your electrical system that may result in a loss of power or excessive heat due to faulty components.

Infrared thermography is an effective tool for identifying these hot spots in electrical systems before they cause any damage.

Infrared thermography is an effective tool for identifying these hot spots in electrical systems before they cause any damage. Thermal imaging can detect hot spots in electrical systems before they cause any damage, which means that it’s a non-destructive method of detecting hot spots in electrical systems.

If a sufficient number of thermal scans are done at regular intervals, patterns can be detected which lead to impending problems.

The more thermal scans you do, the more data you collect. The more data you collect, the more reliable your predictions will be. The more reliable your predictions are, the more time and money you will save.

One of the most important benefits of this predictive maintenance technology is its ability to be used in occupied buildings without disrupting business as usual.

Infrared thermography is able to be used in occupied buildings without disrupting business as usual. Because infrared thermography does not require any physical access to the equipment, there is no need for shutdowns or interruptions of systems. This means that infrared radiation can be applied to non-intrusively inspect and maintain electrical equipment without requiring employees to leave their desks and work areas during hours that are typically busy with customers or clients.

Infrared thermography also allows maintenance professionals to monitor all aspects of an electrical system while maintaining efficiency throughout the plant floor. By using this technology, you will have complete visibility into all operating parameters including voltage level and current draw on each circuit board within your building’s wiring infrastructure (elevators, lighting fixtures etc).

Thermal imaging provides an efficient and cost-effective way to prevent electrical system failures through timely inspections and proactive maintenance practices.

Thermal imaging is a non-destructive testing method that allows for early detection of electrical system failures. It can be used to identify problems before they occur, allowing you to implement proactive maintenance practices and reduce the risk of costly downtime.

Thermography is also cost-effective, since it doesn’t require tearing down equipment or shutting down operations; instead, thermal imaging allows you to detect faults in your electrical systems without disrupting business as usual.

References:

Conclusion

We hope this article has provided you with an understanding of the benefits of infrared thermography and its potential applications in electrical systems. We believe that these benefits justify a systematic approach to inspecting and maintaining all components of your building’s electrical system.

Collegelib.com prepared and published this seminar topic article for Electrical and Electronics Engineering degree students’ seminar topic selection. Before shortlisting your topic, you should do your research in addition to this information. Please include Reference: Collegelib.com and link back to Collegelib in your work.